Objective

Design, build, and install a reliable multibeam SONAR mount around existing vessel.

Highlights

Designed mount to enhance SONAR data quality by minimizing vibration and potential acoustic interference from water turbulence

Designed SONAR mount to be both deployable and retrievable by a single person

Performed entire process -- design, fabrication, testing, installation, and integration -- in-house, by Substructure staff

Project Details

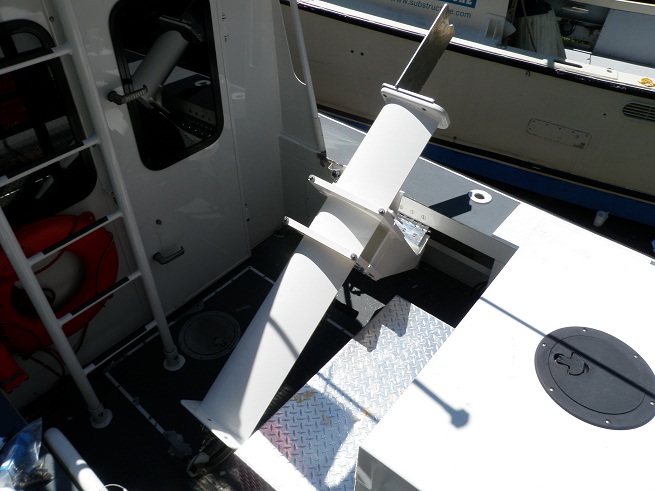

Substructure was selected by the US Army Corps of Engineers (USACE) New England District Survey Section to design, fabricate, install, and integrate multibeam SONAR mounts for two USACE 27-foot aluminum survey launches. Substructure was chosen for this work because of the demonstrated success with our survey vessel, Orion, and because of the District’s strong familiarity with Substructure’s welding, fabrication, and integration capabilities. Substructure designed the mounts around the existing survey launch configuration and to be compatible with existing multibeam echosounders. The mounts were also designed to be compatible with potential future sensor upgrades.

Throughout the design process, Substructure balanced the goal of ensuring high-quality performance of the SONAR with the need to enable relative ease of deployment and recovery. When deployed, the mounting pole had to be rigid and stable to minimize vibration and also had to lock-in at a fixed and consistent position. In addition, the design of the pole and mount had to minimize the potential interference of water turbulence or the boat hull. To meet these goals, we designed and ordered an extruded, faired pole as the primary vertical member and fabricated all of the remaining components (e.g., gunwale mounting plates, mounting bracket and rotation mechanism, SONAR array mounting plate, SONAR nose cone, cable guides, and hull mounting bracket) at our shop.

Final installation on the first of the two 27-foot USACE survey launches took place at the Substructure shop, with subsequent on-water integration and testing conducted locally. This first launch to receive a mount had previously used a single-beam echosounder as the primary acoustic sensor, so this installation also represented a technology upgrade for the survey crew. Despite the use of an older Reson 9001 echosounder, this launch was able to begin successfully acquiring useful multibeam data soon after the installation was complete.

Final installation for the second launch will be completed in winter 2012.