Port Facilities

Substructure designs, fabricates, and installs site-specific operational, maintenance, corrosion-control, and repair equipment and develops customized processes at port facilities.

Our extensive marine rehabilitation experience includes designing and installing customized fendering systems, specialized line-handling mechanisms, and cathodic protection systems. Substructure’s multidisciplinary capabilities allow us to integrate marine corrosion control, hydrographic surveys, and other marine services into our port facility support, resulting in comprehensive solutions tailored to the unique characteristics of a facility. A properly designed, installed, and maintained corrosion-control system can protect facilities and structures for many years. For example, a site-specific impressed-current cathodic protection system can result in 15-20 years of facility protection.

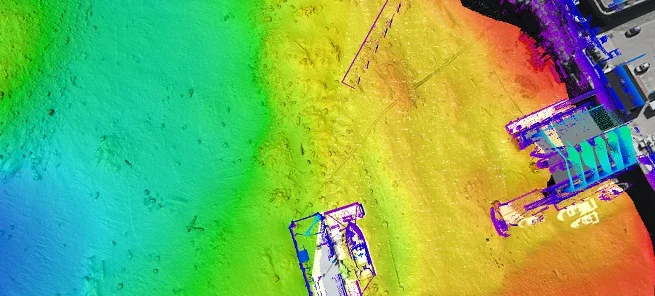

An underused tool by port facilities, high-resolution multibeam hydrographic surveys can provide accurate data about port areas, such as under-keel clearance, whether a contracted area has been dredged to specifications, and the changes and movement of sediment. Survey data can also be useful in making critical port expansion planning decisions.

To learn more about what Substructure can do for your port facility, please contact us today.

Objective: Rehabilitate ship berthing cell while maintaining cargo on-load and off-load capabilities.